COB LED Technology

COB, an acronym for "Chip-On-Board," translates to "chip packaging on the board." This technology directly adheres the bare light-emitting chips to the substrate using conductive or non-conductive adhesive, forming a complete module. This eliminates the need for chip masks used in traditional SMD packaging, thereby removing the physical spacing between chips.

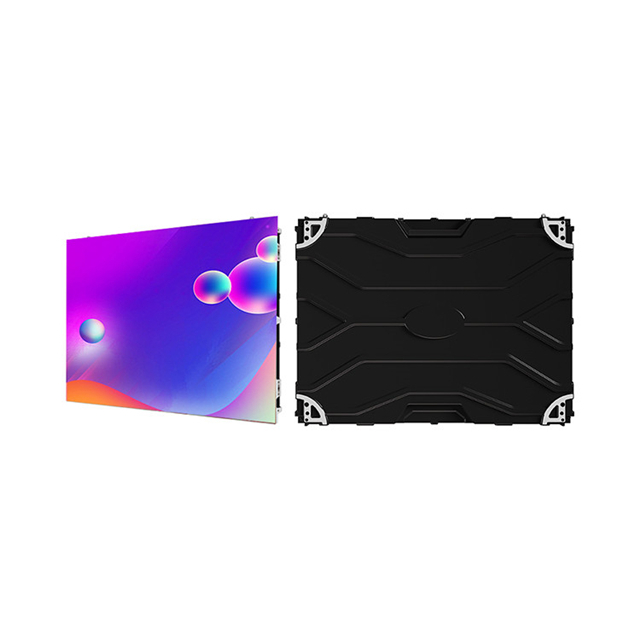

GOB LED Technology

GOB, short for "Glue-On-Board," refers to "gluing on the board." This innovative technology uses a new type of nano-scale filling material with high optical and thermal conductivity. It encapsulates traditional LED display PCB boards and SMD beads through a special process and applies a matte finish. GOB LED displays fill the gaps between beads, akin to adding a protective shield to the LED module, significantly enhancing protection. In summary, GOB technology increases the weight of the display panel while significantly extending its lifespan.

GOB LED Screens Advantages

Enhanced Shock Resistance

GOB technology provides LED displays with superior shock resistance, effectively mitigating damage from harsh external environments and significantly reducing the risk of breakage during installation or transportation.

Crack Resistance

The adhesive's protective properties prevent the display from cracking upon impact, creating an indestructible barrier.

The protective adhesive seal of GOB significantly reduces the risk of impact damage during assembly, transportation, or installation.

The board-gluing technique effectively isolates dust, ensuring the cleanliness and quality of GOB LED displays.

GOB LED displays feature waterproof capabilities, maintaining stability even in rainy or humid conditions.

The design incorporates multiple protective measures to reduce the risk of damage, moisture, or impact, thereby extending the display's lifespan.

COB LED Screens Advantages

Requires only one circuit, resulting in a more streamlined design.

Fewer solder joints decrease the risk of failure.

Post time: Aug-17-2024